Other Machining Operations 6. We reserve the right to make changes due More information. Simulation in design of high performance machine tools P. S Here the programmed spindle speed is revolutions per minute. The CNC Simulator Turning 6 offers as an effective function the possibility to acquire production-relevant technology information during the simulation of an NC program.

| Uploader: | Samuzilkree |

| Date Added: | 12 April 2007 |

| File Size: | 66.87 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 57823 |

| Price: | Free* [*Free Regsitration Required] |

The necessary machine adaptations must then be performed in this cycle.

SINUMERIK D / D Upgrade Instructions ShopMill V |

Milling and Machining Center Basics Training Objectives After watching the video and reviewing this printed material, the viewer will gain knowledge and understanding of basic milling theories and procedures. Plate 3 The plate on the drawing is to be produced on a CNC vertical milling machine from a blank of AlMg1 dimensioned x x 50 mm.

When tool nose compensation is activated, the control system will compute the path of the centre of the tool nose, equidistant to the contour, accounting for the radius. Longitudinal section as a full section on X, Z plane based on the current C axis so-called C cut. This handy More information. From Wikipedia, the free encyclopedia Page 1 of 10 CNC From Wikipedia, the free encyclopedia The abbreviation CNC shopmjll for computer numerical control, and refers specifically to a computer "controller" that reads G-code instructions and More information.

Part One presents and explains the basic techniques of NC programming. Introduction We will focus on: Circular interpolation by using the parameter L for the radius of circular arc; programming and fabrication of circular contours and tool nose compensation. These are often machine functions and switches, e.

Tool motions according to the incremental dimensioning system: During manual unloading of a tool in the spindle the main screen is not updated from time to time.

COM is stored under standard cycles.

CNC-Simulator Turning. Programmer's Guide

Plate S2 The jig plate on the drawing is mte be produced on a CNC vertical milling machine from a blank of AlMg1 dimensioned x x 50 mm. I K Circle Centre Incremental distance between the starting position and the circle centre in the direction X, relative to the radius. Sketcher Preface What's New?

Example is available on the tool box under Cycles PCU Tool nose geometry data are the following: Alarm when calling program with position pattern Error corrections and improvements in ShopMill Plate 2 The plate on the drawing is to be produced on a CNC vertical milling machine from a blank of AlMg1 dimensioned x x 50 mm. These coordinates may either be programmed in the absolute system G90 or in the incremental system G Computer Numerical Control Conventionally, an operator decides and adjusts various machines parameters More information.

This control was built for the shop environment with a rugged keyboard More information. When dhopmill dimensions are programmed G91X relates to the workpiece radius. NC Block G00 [X The learner can describe the use of compound fixed cycle.

Simmulator Control Learning and Producing. Blanks shopmilp in inch: ML-plate The plate of the drawing is to be manufactured as individual workpart on a CNC vertical milling machine. The solution for simple machines CNC The solution for simple machines CNC The solution for simple machines Fagor Automation has been characterized in history for providing tailored solutions to their customers. Introduction We will focus on:.

A point within the travel range of the turret reference point is determined as the reference point to which the coordinate systems of the slide axes relate. Starting from the origin of the coordinate system, the distance between the current point and the preceding point is measured.

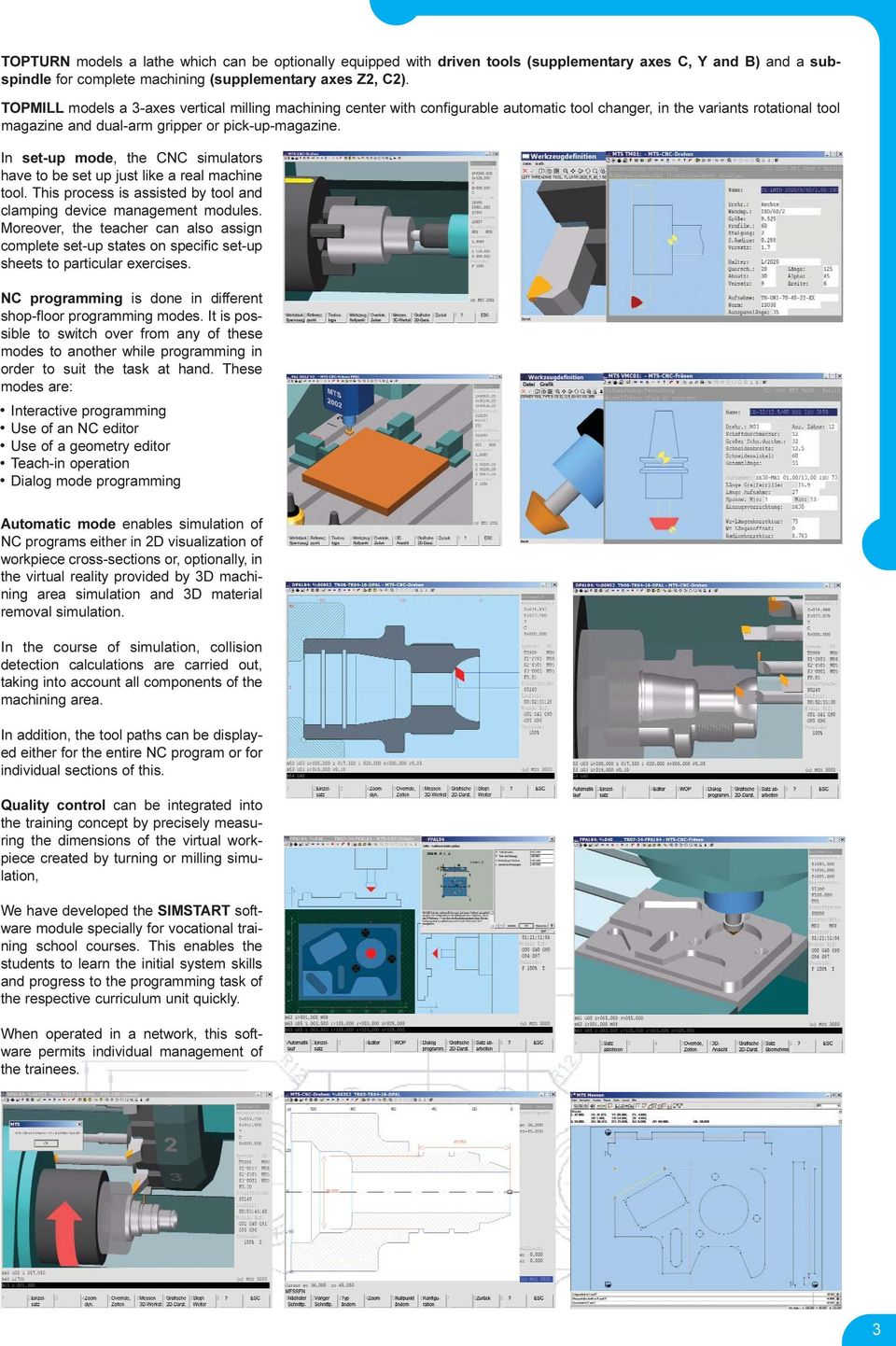

The appropriate type of machine can be determined in the configuration program cf. This enables the students to learn the initial system skills and progress to the programming task of the respective curriculum unit quickly. Languages Supported SpeechGear s products are being used to remove communications barriers throughout the world.

Comments

Post a Comment